Stripping down the rotor blades into single material types

Separation of the composites by ROTH International

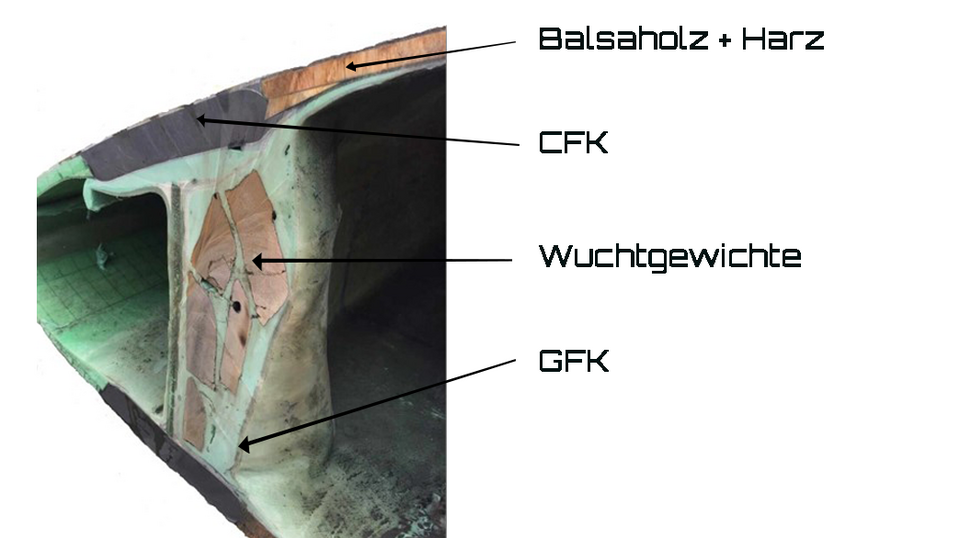

ROTH International disassembles rotor blades neatly into individual materials. We guarantee efficient results thanks to our signature optimized processes. Rotor blades are made of a variety of materials (balsa wood, resin, steel and carbon fiber reinforced and glass fiber reinforced plastics) with a wide variety of properties. As these are difficult to separate, many waste management companies are often not up to the challenge.

Optimized stripping-down by new methods

Years of expertise culminating in innovative separation methods

Many years of experience have yielded many innovations in the field of separation technologies.

ROTH International has been in the business of selective demolition for many years, notably the disposal of rotor blades. Thanks to our advanced cutting, separating and recycling technologies, we take good care of your rotor blades.

ROTH International - your specialist in the field of individual separation technologies for sustainable recycling.

ROTH International is one of a few waste management companies capable of neatly handling the problematic separation of CFRP, GFRP & other materials, even in combination with resin. Continuously advancing the development of separation technologies allows us to optimize of existing processes. This allows us to recycle more effectively and in an environmentally conscious manner.

Building on that know-how, we also possess the skills to separate the materials of other objects.

- Stripping down rotor blades

- Stripping down vessels / boats

- Stripping down aircraft

- Stripping down oil rigs

Neat materials separation for the professional recycling of rotor blades - by ROTH International.

info(at) roth-international.de

roth-international.de

+49-9604-9314040

Give us a call or drop us a line by email.

Complete rotor blade disposal

All from a single source - cutting, stripping-down, recycling and Disposal

Integrated processing of rotor blades.

ROTH International disposes of rotor blades in a particularly environmentally friendly manner. Our comprehensive portfolio ensures that all works and services required for cutting, stripping down, recycling and disposal of your rotor blades - is done exclusively by ROTH International's staff. We make sure that logistical solutions will proceed smoothly thanks to our partnerships with partner companies.

New and innovative cutting and separation methods for successful project handling.

We have to innovative techniques for cutting the rotor blades after dismantling without generating flying sparks, dust, or fragments. Notably the evolution of our separation technologies allows ROTH International to easily separate even materials like composites (CFRP, GFRP).

Virtually residue-free recycling and environmentally friendly disposal of materials.

This allows recoverable materials to be returned to the secondary raw materials market after recycling. Non-recyclable materials will be responsibly disposed of by ROTH International in accordance with Section 56 of the German Closed Substance Cycle and Waste Management Act (KrW-/AbfG).

Stripping down of CFRP / GFRP materials

Advanced separation technologies for composites

Processing of rotor blades and wind turbines.

Rotor blades are those parts of the wind turbine which consist mainly of CFRP / GFRP. These fiber-reinforced plastics are known for causing problems during cutting, separating or recycling. ROTH International's special processes ensure the complete disposal of your rotor blades and the entire wind turbine:

- Cutting up rotor blades

- Recycling rotor blades

- Disposal of rotor blades

- Cutting up wind turbines

- Stripping down wind turbines

- Recycling wind turbines

- Disposal of wind turbines

Cutting, stripping down, and recycling CFRP / GFRP from rotor blades.

Thanks to our experience in selective demolition, we have the skills and capacity for processing and disposing CFRP / GFRP composites:

You need a specialist capable of stripping CFRP / GFRP items down to their individual materials?

info(at) roth-international.de

roth-international.de

+49-9604-9314040

Give us a call or drop us a line by email.

Data Protection

Legal